Automation and SCADA Control Panel Solutions for Enhanced Efficiency and Performance

Automation and SCADA (Supervisory Control and Data Acquisition) systems have revolutionized the way industries operate. Automation involves using machines or computer programs to perform tasks that were once done manually by humans. SCADA, on the other hand, refers to the use of software and hardware systems to remotely monitor and control industrial processes.

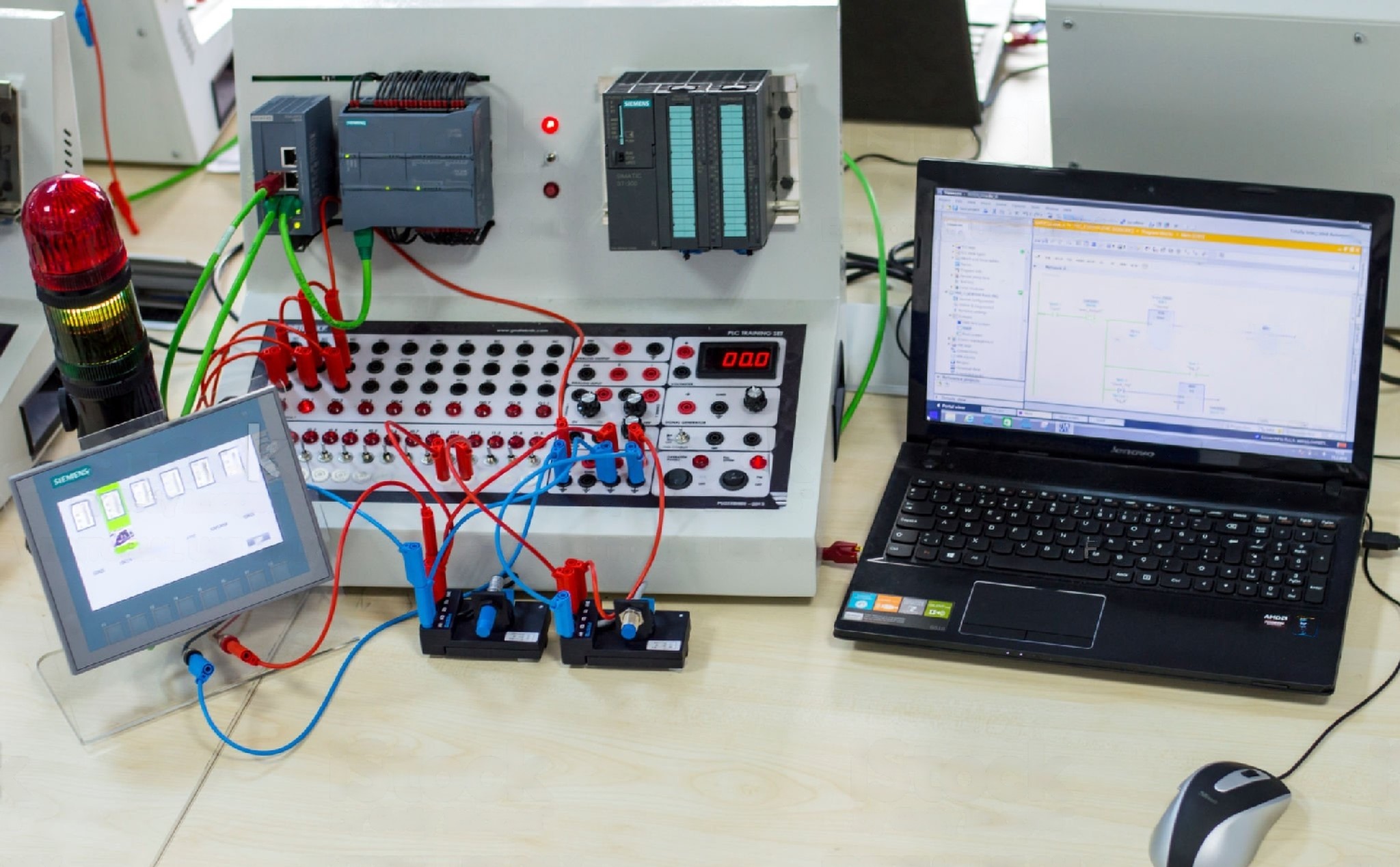

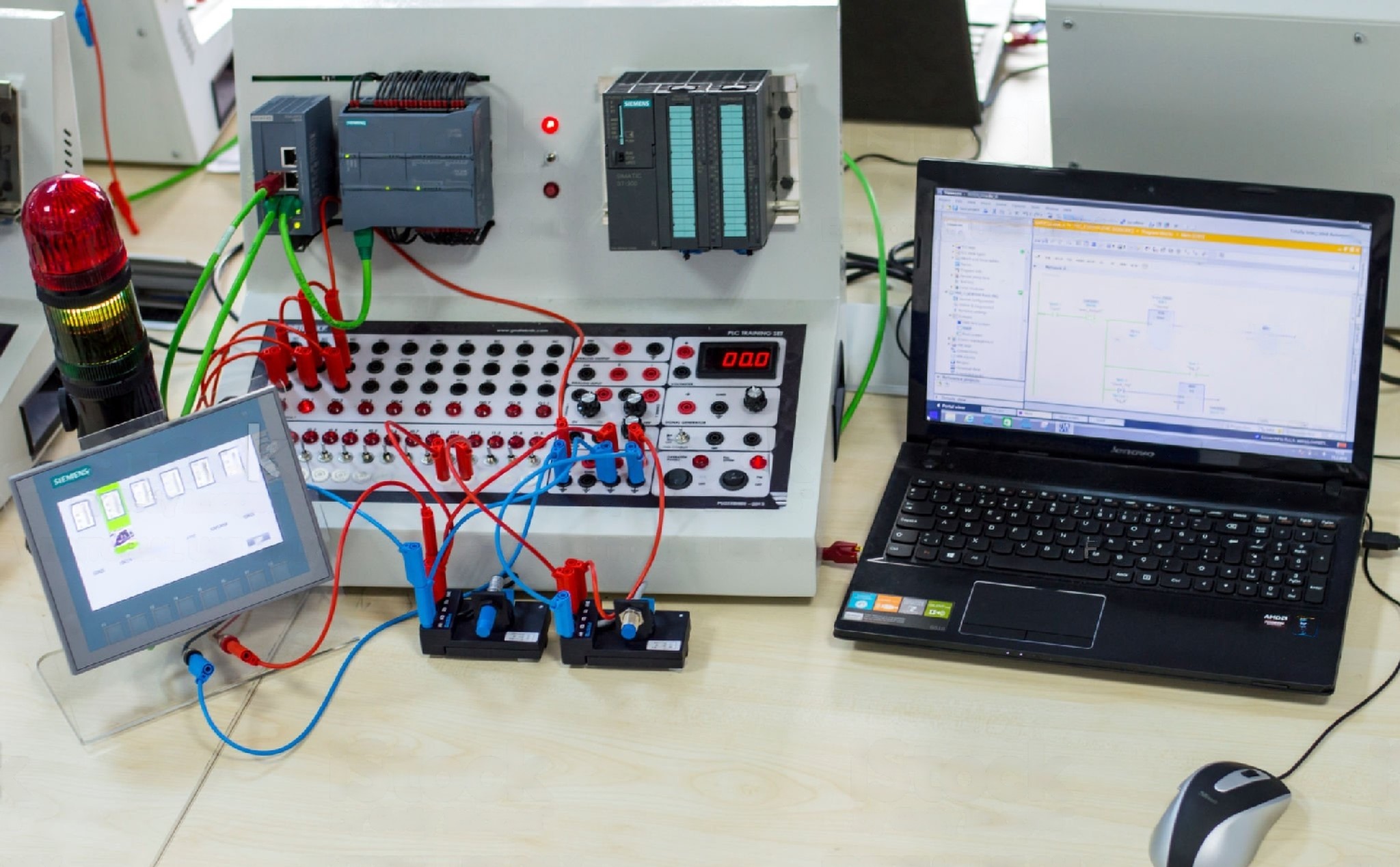

Automation and SCADA control panels are essential components in modern industrial processes, providing real-time monitoring and control of equipment and processes. They enable operators to remotely monitor and control various equipment, such as pumps, valves, motors, and sensors, from a central location. This results in more efficient and effective management of industrial processes, with improved reliability, productivity, and safety.

The benefits of automation and SCADA control panel systems include increased efficiency, reduced downtime, improved safety, and lower costs. Automation enables industries to perform tasks faster, more accurately, and with greater precision than manual methods. SCADA control panels provide operators with real-time information about the performance of their equipment, enabling them to make informed decisions about maintenance and repairs.

Moreover, automation and SCADA control panel systems are highly customizable, allowing industries to tailor them to their specific needs. This means that businesses can integrate their systems seamlessly into their existing operations, reducing the need for major changes or overhauls.

In conclusion, automation and SCADA control panel systems have become essential tools for industries that aim to achieve optimal efficiency, productivity, and safety in their operations. With the right systems in place, businesses can reduce costs, minimize downtime, and increase profitability, while also ensuring that their processes remain safe and compliant with regulations.

The Role of SCADA Control Panels in Industrial Automation

Supervisory Control and Data Acquisition (SCADA) control panels play a critical role in modern industrial automation systems. They are used to control and monitor industrial processes and equipment, collect and analyze data in real-time, and provide operators with a comprehensive view of the entire system.

SCADA control panels are essential for managing complex automation systems. They enable operators to remotely control and monitor processes, equipment, and devices from a centralized location. With a SCADA control panel, operators can access real-time data from various sensors and devices throughout the system, enabling them to make informed decisions quickly.

SCADA control panels also facilitate data storage and analysis, providing operators with valuable insights into system performance, equipment status, and overall productivity. By analyzing historical data, operators can identify trends and patterns and make informed decisions about system upgrades, maintenance, and optimization.

In addition, SCADA control panels help improve system reliability and reduce downtime. They can alert operators to potential issues, such as equipment failures or deviations from set parameters, allowing them to take corrective action before problems escalate.

Overall, SCADA control panels are a crucial component of modern industrial automation systems. They enable operators to manage complex processes, optimize productivity, and ensure system reliability and uptime.

Maximizing Efficiency with Automation Solutions

Automation solutions can help businesses of all sizes and industries to maximize their efficiency and productivity. By automating repetitive and time-consuming tasks, businesses can free up valuable time and resources, allowing them to focus on more critical tasks. Automation can also reduce errors and improve quality control, resulting in higher-quality products and services.

Additionally, automation can help businesses to respond more quickly to changing market conditions and customer demands, as well as improve their competitiveness by reducing costs and increasing output. Automation solutions can range from simple process automation to complex robotics and machine learning systems, and can be customized to meet the specific needs of each business. By embracing automation, businesses can stay ahead of the competition and position themselves for long-term success.

SCADA Control Panel Design and Implementation

SCADA (Supervisory Control and Data Acquisition) systems are critical components of industrial automation, used to monitor and control processes in real-time. A SCADA control panel is a hardware and software system that is designed to collect data from various sensors and devices, process the data, and provide real-time feedback to operators.

The design and implementation of a SCADA control panel are critical to ensure that the system is reliable, secure, and meets the specific needs of the application. The panel should be designed to provide clear and concise information to the operator, with intuitive controls that allow for quick and accurate responses.

Effective implementation of a SCADA control panel requires close collaboration between the automation provider and the client to ensure that the system is customized to meet specific requirements. The system should be thoroughly tested and validated before deployment, and ongoing support and maintenance should be provided to ensure its continued reliability and optimal performance.